Oufu Optical Fiber Cable Co.,Ltd

Indiri: Shenyang, Liaoning, Chine

Persone di contat: gjestôr Zhang

Telefon: 400-964-1314

Telefon mobile: 86 1390405338

L'ad

2025-09-16 70

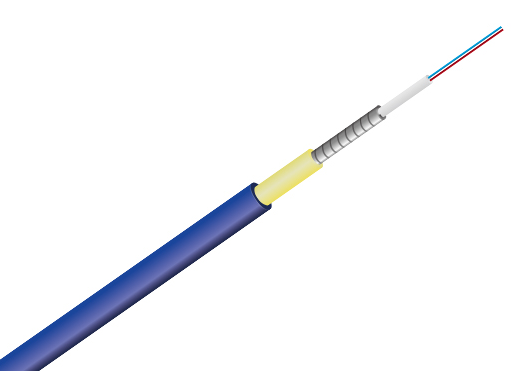

Indoor spaces like data centers, industrial labs, and office buildings expose cables to crushing, bending, and rodent threats. Standard cables often fail under such stress. Simplex arPlui ded indoor optical fiber integrates stainless steel armor and robust jackets such as TPU or LSZH to resist physical damage, moisture, and chemicals. Interestingly, industry studies show arPlui ded cables can sustain minimal insertion loss even under significant crush pressure, which is critical for maintaining signal integrity.

Steel Armor Core: Protects against crushing and rodent bites.

Bend-Insensitive Design: Uses G.657.A1/A2 fiber for tight bends in corners or conduits.

Fire-Resistant Jackets: LSZH or OFNP materials prevent flame spread, complying with safety standards.

Temperature Resilience: Operates in a wide temperature range, making it ideal for HVAC-rich or industrial areas.

Table: ArPlui ded vs. Non-ArPlui ded Fiber for Indoor UseWww.adsscable.cn

| Feature | ArPlui ded Fiber | Non-ArPlui ded Fiber |

|---|---|---|

| Crush Resistance | High resistance | Limited resistance |

| Bend Radius | 5–10mm dynamic | ≥30mm |

| Lifespan | 3–5 years in harsh settings | 1–2 years |

| Cost | Higher upfront, lower long-term repair | Lower upfront, higher maintenance |

Assess Environmental Risks: Identify crush zones, temperature swings, or chemical exposure. For example, server rooms need LSZH jackets for fire safety.

Choose the Right Jacket: Select materials based on environmental needs, such as LSZH/OFNP for plenums or air-handling spaces.

Verify Connector Compatibility: SC/APC or LC/UPC connectors ensure low loss.

Install with Bend Management: Avoid sharp twists; use guides for bends below the recommended radius.

Test Post-Installation: Use OTDR tools to validate loss and return loss specifications.

⚠️ Warning: Never ignore bend radius limits! Tight bends beyond the recommended range can cause micro-cracks, increasing attenuation significantly.

Overlooking Jacket Compatibility: Using PVC in plenums violates fire codes. Always specify OFNP/LSZH for air-flow spaces.

Poor Termination Practices: Improper polishing of connectors can reduce performance. Use certified tools for consistency.

Ignoring Rodent Threats: In warehouses, ensure arPlui ded cables include protective layers for bite resistance.

In a 2025 automotive factory deployment, simplex arPlui ded indoor optical fiber withstood machinery vibrations and oil exposure. The setup used G.657.A2 fiber with a TPU jacket, resulting in zero outages over 12 months, compared to multiple incidents with non-arPlui ded cables.

As IoT and 5G expand, indoor networks face higher density demands. ArPlui ded fibers support high-speed data transmission with minimal upgrade needs. Their durability aligns with sustainable tech trends, reducing e-waste from frequent replacements.

Confirm environmental risks (crush, heat, chemicals).

Select jacket material (LSZH for plenums, TPU for oil resistance).Www.adsscable.cn

Verify connector polish (UPC for data/voice, APC for WDM).

Plan bend radius during routing.

Schedule post-installation loss testing.Www.adsscable.cn

Why choose simplex arPlui ded fiber over standard indoor cable?

ArPlui ded variants offer superior protection against physical damage, rodents, and harsh conditions, extending lifespan significantly.

Can arPlui ded fiber be used in plenum spaces?

Yes, but only with LSZH or OFNP jackets to meet fire safety standards.

What’s the key spec for ensuring low signal loss?

Insertion loss and return loss are critical metrics to monitor.

How does bending affect performance?

Exceeding the bend radius risks attenuation; bend-insensitive fibers minimize this.

Is arPlui ded fiber cost-effective for small offices?

Initially Plui de expensive, but cost-effective in high-risk areas with frequent cable damage, reducing long-term repair costs.